At our lab, we blend high-performance materials, cutting-edge manufacturing techniques, and advanced computational methods to engineer the next generation of multifunctional structural mechanisms. Grounded in theoretical and numerical models, we leverage material and structural nonlinearities to design mechanical systems with unique and exceptional properties.

Smart solid-state actuators can significantly minimize the number of moving parts in mechanisms, leading to increased reliability, reduced maintenance, and enhanced performance. Unlike traditional actuators, which rely on mechanical components to produce motion, smart solid-state actuators utilize materials that can change shape, size, or properties in response to external stimuli, such as electric fields, magnetic fields, or temperature changes. This capability allows for more compact and lightweight designs, making them particularly valuable in aerospace applications.

In the aerospace sector, where weight reduction is critical, these actuators offer significant advantages by replacing bulky, heavy mechanical systems with streamlined, efficient alternatives. Their ability to perform precise, rapid, and energy-efficient movements without the need for complex gears or hydraulics makes them ideal for various aerospace uses, including unmanned aerial vehicles (UAVs) and reconfigurable space structures. By enabling lighter, more versatile designs, these actuators are driving the advancement of the next generation of UAVs and space technologies capable of adaptive, multi-functional performance.

Integrating stimuli-responsive materials with structural composites enables the creation of structures that can support significant loads while adapting their structural characteristics in response to changing ambient conditions.

Multifunctional composites represent a class of advanced materials designed to combine multiple properties into a single system, offering enhanced performance and functionality. Unlike traditional composites that primarily focus on structural strength and lightweight characteristics, multifunctional composites integrate additional capabilities, such as thermal conductivity, electrical conductivity, self-sensing, energy storage, and even self-healing. This convergence of properties enables new design possibilities and makes these materials highly valuable across various industries, including aerospace, automotive, and energy sectors.

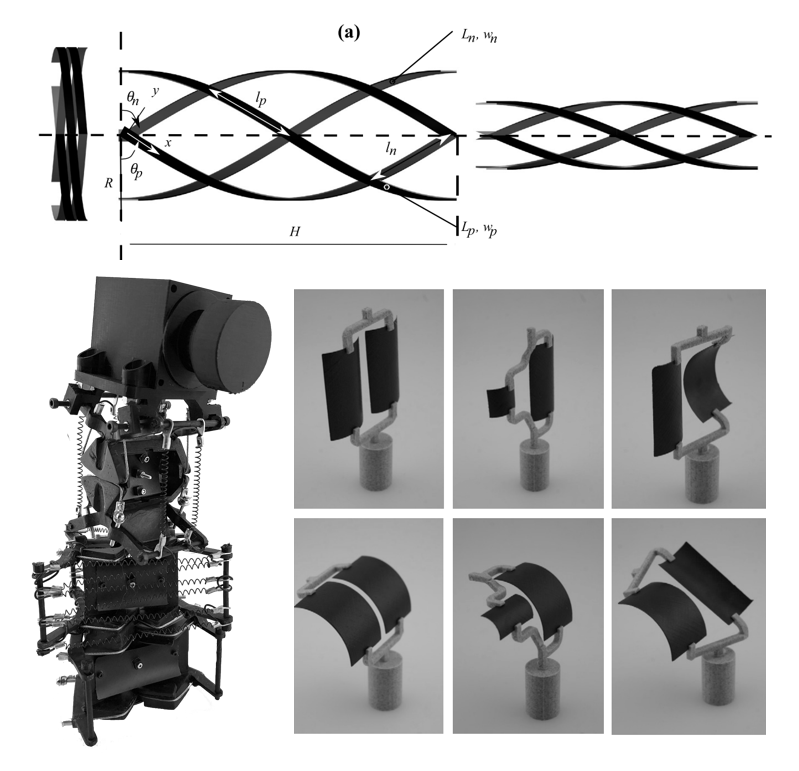

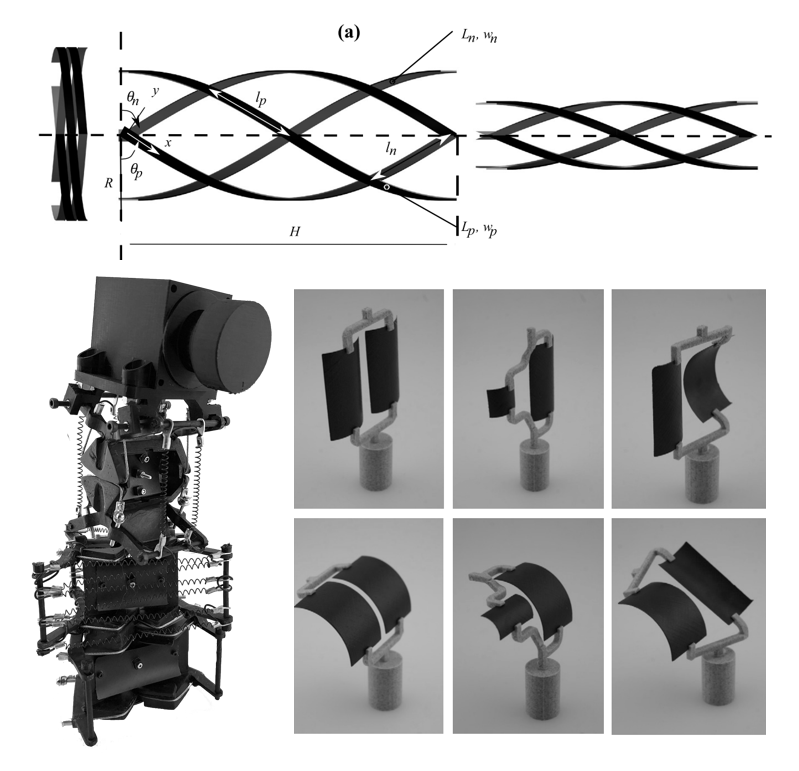

Reconfigurable space structures are an emerging technology that enables spacecraft and satellites to adapt their shape, configuration, or functionality while in orbit. Unlike traditional rigid structures, which are fixed in design and function, reconfigurable structures can change to meet different mission requirements, respond to environmental conditions, or perform multiple tasks. This adaptability makes them ideal for a range of applications, from satellite communications and observation to deep-space exploration.

A key feature of reconfigurable space structures is their ability to deploy and transform once in space. Traditional spacecraft design often involves folding or compacting large components to fit within the limited space of a launch vehicle. Reconfigurable structures take this concept further by not only deploying into a larger form but also reconfiguring or morphing their shape as needed during the mission. This ability is enabled by advanced materials, such as shape memory alloys, bistable composites, and other smart materials that can change shape when exposed to stimuli like temperature or electrical signals.

Reconfigurable space structures are an emerging technology that enables spacecraft and satellites to adapt their shape, configuration, or functionality while in orbit. Unlike traditional rigid structures, which are fixed in design and function, reconfigurable structures can change to meet different mission requirements, respond to environmental conditions, or perform multiple tasks. This adaptability makes them ideal for a range of applications, from satellite communications and observation to deep-space exploration.

A key feature of reconfigurable space structures is their ability to deploy and transform once in space. Traditional spacecraft design often involves folding or compacting large components to fit within the limited space of a launch vehicle. Reconfigurable structures take this concept further by not only deploying into a larger form but also reconfiguring or morphing their shape as needed during the mission. This ability is enabled by advanced materials, such as shape memory alloys, bistable composites, and other smart materials that can change shape when exposed to stimuli like temperature or electrical signals.

Indian Institute of Technology

Kharagpur,

West Bengal 721302

Phone No 03222282918